Introduction

Butt Fusion

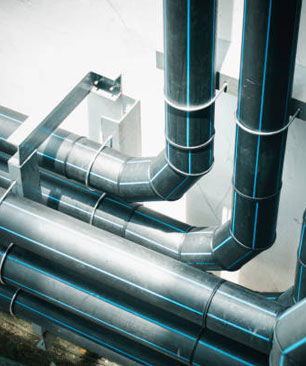

Butt Fusion welding is a type of welding procedure used to join two pieces of thermoplastic together. The most common types of thermoplastic materials that are fusion welded are HDPE, PP, PVC, PS, PETE, and PC. Fusion welding is performed by heating the two pieces of thermoplastic material until they are soft enough to be joined together. The two pieces are then placed together and allowed to cool.

There are several benefits to using fusion welding over other types of welding methods. Fusion welding provides a stronger joint than other methods, such as mechanical fastening or adhesive bonding. Fusion welding also allows for a wider range of materials to be joined together, including dissimilar materials. Additionally, fusion welding is suitable for both small and large-scale applications. The process of butt fusion

You can find many different brands of butt fusion machines on the market, but Hydroplast is widely considered to be one of the best brand in Pakistan. That’s because Hydroplast machines are known for their durability. In addition, Hydroplast butt fusion machines are easy to use, making them a good choice for those who are new to this type of welding. Finally, Hydroplast machines are backed by a strong warranty, so you can be confident that you’re getting a quality product.

Hydroplast has been manufacturing butt fusion machines since 1984, and their experience shows in the quality of their machines. Hydroplast machines are made from high-quality materials, and they’re built to last.

Butt fusion vs other joining methods

There are many ways to join two pieces of pipe together, but butt fusion is widely considered the best method. Butt fusion involves heating the ends of the pipes until they are soft enough to meld together. Other joining methods include:

Butt Fusion

The challenges of butt welding

Many challenges come with butt fusion. First, it is important to make sure that the joint is clean and free of debris. If there is any debris on the joint, it can cause the weld to be weak and may eventually lead to failure. Second, it is important to properly align the pipes before welding them together. If the pipes are not properly aligned, the weld will be weaker and may eventually fail. Finally, it is important to make sure that the weld area is cooled properly after welding. If the weld area is not cooled properly, it can cause the weld to be weak and may eventually lead to failure.

butt fusion is a quick and easy way to join two pieces of PVC pipe together. It is a permanent, watertight connection that can be used on pipes for 2m in diameter. Butt fusion is also a cost-effective method of joining thermoplastic pipe, making it a popular choice for many home and commercial applications.

Hope you enjoyed reading this blog about the butt fusion machine and its process. Hydroplast is one of the top brands in the butt fusion technology in Pakistan, if you have any questions please check out our FAQ section.

Are you in the market for a butt fusion machine? If so, you’ve come to the right place. We’ll tell you everything you need to know about butt fusion machines, including how they work and what brands are considered to be the best.

FAQ

Can different grades of thermoplastic be fused using butt fusion?

Yes, different grades of thermoplastic can be connected using butt fusion. However, it is important to note that the lower the grade of thermoplastic, the more difficult it is to achieve a strong connection. In addition, it is also important to make sure that the surfaces to be joined are clean and free of any contaminants before attempting to fuse them

What training is necessary for operatives to assemble thermoplastic pipe networks?

In order for operatives to be able to assemble thermoplastic pipe networks using butt fusion, they will need to receive proper training. This training will teach them how to properly align the pipes that need to be joined, as well as how to use the correct amount of pressure and heat. They will also need to learn how to check the finished joint for any leaks. Without this training, it would be very difficult for operatives to successfully assemble a thermoplastic pipe network using butt fusion.

How can I verify that the proper assembly instructions were followed?

As more and more people move towards do-it-yourself projects, the need for guidance on proper assembly techniques increases. Butt fusion is a type of welding often used in the construction and repair of pipelines and other types of metalwork. While butt fusion is not difficult to learn, the proper assembly instructions must be followed in order to ensure a safe and successful weld.

There are a few key things to look for when verifying that the proper assembly instructions for butt fusion were followed. First, check to make sure that the two pieces of metal being joined are clean and free of debris. Next, align the two pieces so that they are flush with each other. Once aligned, clamp them together so they will not move during the welding process. Now you are ready to begin welding.

What methods are employed to test the assembly?

Two main methods are used to test the assembly of butt fusion joints.

- The first method is called the peel test. This test is conducted by applying a load to the joint until it fails. The amount of force required to cause the joint to fail is then recorded.

- The second method is known as the side-by-side technique. This method involves welding two specimens together and then testing them both in tension. The amount of force required to cause failure in each specimen is then recorded and compared.

Both of these methods are effective at testing the strength of butt fusion joints. However, the peel test is generally considered to be more reliable as it can provide more accurate results.

What is the difference between Butt Fusion and Electrofusion?

There are two main types of HDPE pipe fusion: butt fusion and electrofusion. Butt fusion involves heating the ends of two pipe sections and then pressing them together to form a continuous joint. Electrofusion involves wrapping an electrical heating element around the outside of a pipe section. The element creates enough heat to melt the HDPE and weld the seams of the joint together.

So, what’s the difference between butt fusion and electrofusion? The main difference is in the amount of heat that is required to fuse the pipes. Butt fusion requires less heat, so it is ideal for fusing large-diameter pipes. When using butt fusion welding, a rig is needed to make sure the pipes are level and have flat faces as they are forced together to create a continuous seal around the junction. The size of the rigs varies according to the pipe diameter that is being utilized, butt fusion is commonly offered for pipe sizes between 50mm and 2m.

In contrast, electrofusion uses a collar in which the two pipe ends are placed. An electric current is then run through the collar, melting the pipe’s exterior and fusing it to the collar as seen in the sketch below. Once attached, the collar remains on the pipe and becomes a part of the pipeline. Electrofusion is a viable solution for pipes with a diameter of 16mm to 710mm2. Electrofusion joints are not suitable for “no-dig” techniques like auger bore or directional drilling since they remain with a collar on. The collar, as you might expect, makes it extremely challenging to push or drag the welded pipe into the ground.

Electrofusion requires more heat, so it is better suited for fusing smaller-diameter pipes.

From where I can buy quality but fusion in Pakistan.

Hydroplast is one of the top manufacturers of quality fusion machines in Pakistan. The company has been in business for over 4 decades and has a solid reputation for providing high-quality products and services. Hydroplast offers a wide range of fusion machines, including those for welding, cutting, and bending.